Knitted Mesh-Width 1100mm

JHJ knitted wire mesh tapes are constructed from a fine wire into a double layflat stocking and are available in widest range of materials and widths available according to the oder. The tape is highly flexible,light,corrosion and high temperature resistant but also stronger and more resistant to abrasion and physical damage than other tape materials. Tapes are available in widths from 6mm wide up to 1000mm wide and can be produced with a crimp to give greater thinkness than standard. Application Mesh tapes are primarily used for shielding electrical and electronic cable assemblies ,for cable jointings ,grounding ,static discharge and within connector assemeblies . Normally the mesh should be applied to a cable with a 50% overlap to provide a 4 layer shield and terminated at each end by means of clamping, soldering or spot welding. Wide kind of Materials The most commonly used wires, filaments and yarns are listed in the table opposite, however please contact us f the material you need is not shown. Round wires from 0.11mm to 0.35mm diameter are most commonly knitted, but for special applications it is possible to knit wire as small as 0.03mm or as large as 0.8mm in diameter. Flattened wires and multi-filament knitting can be used to increase surface area.

| Material | Wire Diameter |

| Monel ( ASTM B 164 ) | 0.10mm |

| Tin Plated Copper Glad Steel ( Sn/Cu/Fe) | 0.10mm |

| Stainless Steel (AISI 304) | 0.10mm |

| Tinned Copper (SJ 2422-1983 ) | 0.10mm |

| Silver Glad Copper | 0.10mm |

| Nickel Plated Copper | 0.10mm |

| Aluminium (GB/T 3955-2009) | 0.10mm |

| Coppers (GB/T 3953-2009) | 0.10mm |

| Brass (B/T 14954-1994) |

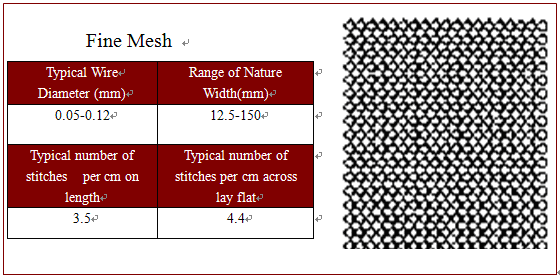

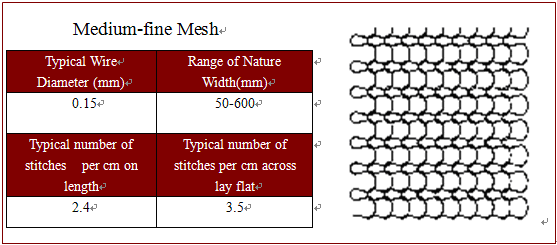

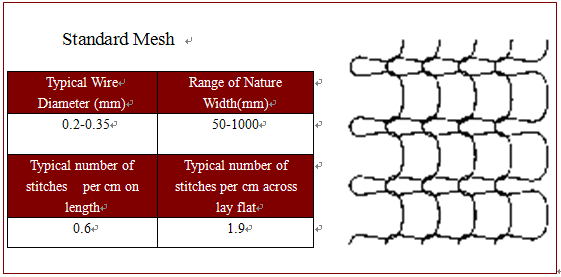

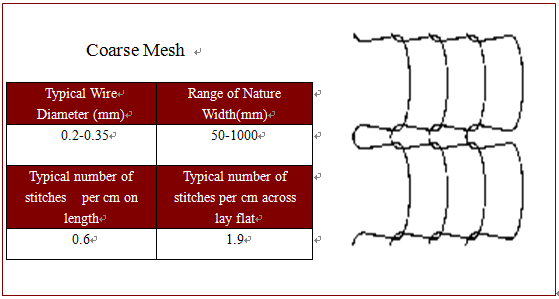

Types of Knitted Mesh Mesh is usually specified by the number of stitches per cm. The range of meshes is considerable but for practical purposes these are from 0.5 stitches per cm to 6 stitches per cm. Meshes can be grouped into five broad categories: fine, medium-fine, standard, coarse and super-coarse, but these divisions can cover a wide range of products. Using various filament diameters and mesh sizes, along with different crimping, calendaring, folding, layering and rolling processes, the product scope is almost unlimited.